In the world of metal forming, a progressive stamping die stands out as a powerhouse for efficient, high-volume production. If you’re in manufacturing, engineering, or procurement, understanding progressive stamping dies can transform how you approach part creation. This guide dives deep into what makes these tools essential, how they operate, and why they’re a go-to for precision components. Whether you’re curious about the basics or seeking advanced insights, we’ll cover it all with practical examples and tips.

Progressive stamping dies enable the creation of complex metal parts through a series of stations in a single die set. As raw material feeds through, each station performs operations like punching, bending, or coining, resulting in finished parts with minimal waste. This process is ideal for industries demanding speed and accuracy, such as automotive and electronics.

What Is a Progressive Stamping Die?

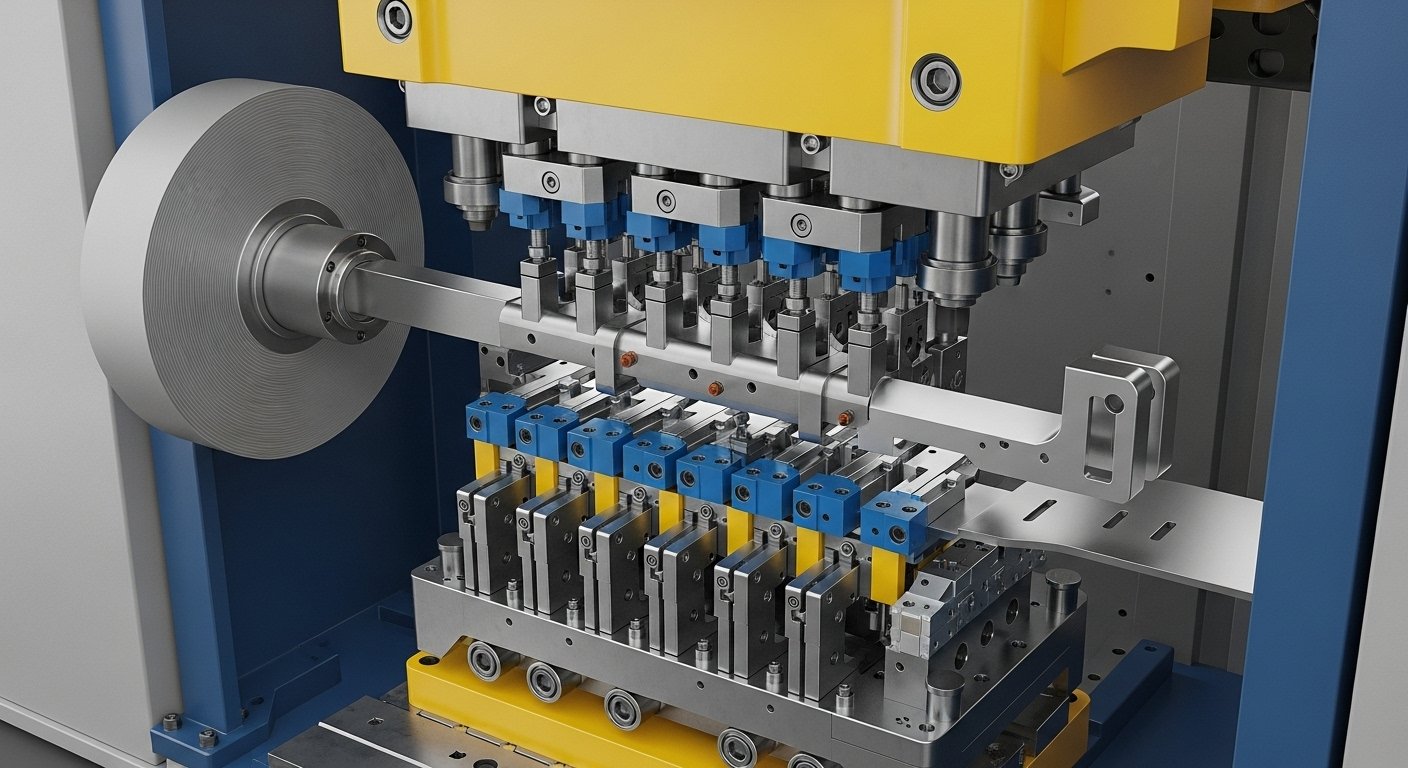

A progressive stamping die is a specialized tool used in metalworking to shape and cut metal strips into precise parts. Unlike single-stage dies, it features multiple stations where sequential operations occur as the material advances. This setup allows for automated, continuous production, making it perfect for medium to high-volume runs.

Think of it like an assembly line within a press: the metal coil unrolls, feeds into the die, and emerges as completed components. Key elements include the die block, punches, pilots for alignment, and strippers to eject parts. For instance, in producing a simple bracket, one station might punch holes while the next bends edges—all in one cycle.

This design minimizes manual intervention, reducing errors and costs. According to industry standards, progressive dies can handle tolerances as tight as ±0.001 inches, ensuring repeatability.

How Do Progressive Stamping Dies Work?

Progressive stamping dies operate within a reciprocating press, where the upper and lower die halves come together with each stroke. The process begins with a coil of metal (like steel or aluminum) being fed into the system via a straightener and feeder.

Key Components of a Progressive Stamping Die

- Die Set: The core structure housing all stations.

- Feeder: Advances the metal strip precisely, often using pilots for alignment.

- Press: Provides the force, ranging from 10 to 600 tons depending on material thickness.

- Stripper Plate: Removes the stamped part from the punch.

- Carrier Strip: Holds parts together during progression until separation.

Other components, like sensors for monitoring, ensure smooth operation and prevent jams.

The Progressive Stamping Process Step-by-Step

- Material Feeding: The coil is uncoiled and straightened.

- Initial Station: Performs basic cuts or punches.

- Progressive Operations: As the strip moves, subsequent stations bend, form, or emboss.

- Final Separation: The last station cuts the part free, often ejecting it via conveyors.

- Cycle Repeat: The press strokes continuously, producing parts at rates up to 1,500 per minute.

For example, manufacturing a beverage can lid involves progressive stations for drawing the shape, adding tabs, and sealing edges. This efficiency contrasts with manual methods, where each step requires separate tools.

Benefits of Progressive Stamping Dies

Why choose progressive stamping dies over alternatives? The advantages are clear and impactful.

First, they offer high-speed production, slashing lead times. A single operator can oversee runs of millions of parts, cutting labor costs by up to 50%. Waste is minimized through optimized layouts, often reducing scrap to under 10%.

Repeatability is another win—each part matches the last, vital for quality control in regulated industries. Long run lengths make them cost-effective; initial tooling investment pays off quickly in volume scenarios.

Additionally, progressive dies support complex geometries without secondary operations, enhancing design freedom. Compared to traditional stamping, they boost output while maintaining precision.

Have you ever wondered how everyday items like connectors or brackets are made so uniformly? Progressive stamping dies are often the answer, delivering consistency at scale.

Applications of Progressive Stamping Dies Across Industries

Progressive stamping dies shine in diverse sectors, producing everything from tiny electronics to robust automotive components.

1. Automotive Industry

In vehicles, these dies create brackets, clips, and terminals. Their ability to handle high-strength steels ensures durability for safety-critical parts like airbag housings.

2. Electronics and Appliances

Think circuit board shields or appliance hinges—these require precise, thin-metal forming. Progressive dies excel here, producing intricate shapes for smartphones and refrigerators.

3. Medical Devices

For sterile, accurate components like surgical clips, the process offers clean cuts and tight tolerances, complying with FDA standards.

4. Food and Beverage

Can lids and tabs are classic examples, where speed meets hygiene requirements.

5. Aerospace and Renewable Energy

Exotic alloys for turbine parts or solar panel frames benefit from the dies’ versatility.

Real-world case: A major automaker uses progressive stamping for fuel injector clips, achieving 99.9% defect-free rates.

Materials Used in Progressive Stamping

Selecting the right material is crucial for progressive stamping success.

Common Metals

- Steel: Versatile and strong; low-carbon variants for easy forming.

- Aluminum: Lightweight, corrosion-resistant; ideal for electronics.

- Copper Alloys: Excellent conductivity for electrical parts.

- Stainless Steel: For medical or food applications needing rust resistance.

Exotic options like titanium suit aerospace, though they demand specialized tooling.

Factors like thickness (0.005–0.250 inches) and ductility influence die design. Always test materials to avoid cracking during deep draws.

Progressive Stamping Die vs. Other Stamping Methods

Not all stamping is equal. Let’s compare progressive dies to alternatives.

1. Compound Die Stamping

Compound dies perform multiple operations in one stroke but suit simple, low-volume parts. Progressive wins for complexity and speed.

2. Transfer Die Stamping

Transfer dies move individual blanks between stations, great for large parts but slower and costlier than progressive for coils.

3. Traditional or Single-Stage Stamping

Manual and basic, this lacks automation, making it inefficient for high volumes.

In short, if your project involves coils and sequences, progressive stamping dies offer superior efficiency.

Design Considerations for Progressive Stamping Dies

Effective die design starts with CAD software, factoring in part geometry, material flow, and station sequencing.

Key tips: Use pilots for alignment, incorporate scrap cutters early, and simulate with FEA to predict stresses. Tool steel construction withstands high loads, while coatings reduce wear.

Common pitfalls? Poor carrier design can cause buckling—opt for stretch webs in deep forms.

For internal linking, consider related topics like “Metal Stamping Basics” or “Choosing Between Progressive and Deep Draw Stamping.”

Choosing a Progressive Stamping Die Manufacturer

Partner with experts who offer in-house tooling and quality certifications like ISO 9001. Look for experience in your industry and capabilities for custom dies.

Questions to ask: What’s your lead time? Do you handle prototypes?

In conclusion, progressive stamping dies revolutionize manufacturing by combining speed, precision, and cost savings. As technology advances, expect even smarter dies with AI monitoring. If efficiency is your goal, embracing this process could be a game-changer. Ready to optimize your production? Explore progressive stamping dies today.

Explore More Topic: How to Remove Apple ID from AirPods

FAQ

What is the difference between progressive die stamping and transfer die stamping?

Progressive die stamping uses a continuous coil fed through multiple stations, ideal for high-volume small parts. Transfer die stamping handles individual blanks moved between stations, better for larger or complex items requiring part separation early.

How much does a progressive stamping die cost?

Costs vary from $5,000 for simple dies to over $100,000 for complex ones, depending on stations, material, and precision. Factor in long-term savings from high production runs.

What industries benefit most from progressive stamping dies?

Automotive, electronics, medical, appliances, and aerospace see the greatest advantages due to the need for precise, high-volume metal components.

Can progressive stamping dies handle thick materials?

Yes, up to 0.250 inches or more, but thicker materials require higher-tonnage presses and robust die designs to prevent wear.